What Is a Phenolic Foam Duct Panel?

[ad_1]

A house or a commercial building is not complete without proper insulation. Nowadays, the effect of global warming is taking toll at both skyscrapers and bungalows that is why it is crucial to take proper measures (even at an additional cost) to reinforce the building. Insulation helps keep warm air out during warm months and in during cold months. The most common insulation materials are sheet metals such as galvanized steel and aluminum. Because these are metals, their price fluctuates from time to time. In addition, they can be heavy and costly when transported in very large amounts. Aside from using galvanized steel and aluminum, fiberglass duct panels are also used.

The insulative properties of fiberglass are far superior to that of aluminum or galvanized metal. However, fiberglass is also more expensive. Galvanized steel, aluminum and fiberglass all have their applications in industry today. However, there are some applications in which the use of these materials would be too costly or inconvenient. This is where architects and engineers use insulative foams.

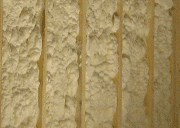

Polyurethane and phenolic foam are the most commonly used resin foam duct panels. They are lightweight and more affordable than steel, aluminum and fiberglass. These panels can be used to line walls, floors, ceilings and air ducts. They can be made rigid or flexible. Most, if not all phenolic foam duct panels are lined with a thin layer of aluminum (25 micrometers for interior use and 200 micrometers for exterior use) on both sides to reinforce its insulative properties. Phenolic foam is a type of resin (plastic) that is composed of aldehyde and phenol.

What sets this type of foam duct panel apart from other building insulators is its fire performance and moisture resistance. It will not melt when it comes in contact with fire. Flames have zero to very little chance of spreading once they come in contact with this foam. Also, the foam produces very negligible amounts of non-toxic smoke (composed of CO2 and CO only) when burnt.

In order to maintain the quality, the foam comes with several standardized fire certifications. The best variety is closed cell phenolic foam due to its high thermal performance. Very little moisture can penetrate through this kind of foam. If the foam is punctured, the moisture will stay on the punctured area and will not be absorbed by the foam.

Overall, phenolic foam is a dependable material for both industrial and commercial use.

[ad_2]